EOT Crane Wiring Diagram with Motor, Contactor, VFD, Remote

Hey, in this article we are going to see the complete EOT crane Wiring Diagram and Connection with Motors, Contactors, VFDs, Remote controllers, Switches, etc. EOT crane Full Form Electric Overhead Travelling Crane. It is also known as Bridge Crane. It is the most common type of overhead crane used for lifting and moving heavy material in manufacturing industries. It consists of parallel runways with a traveling bridge spanning the gap.

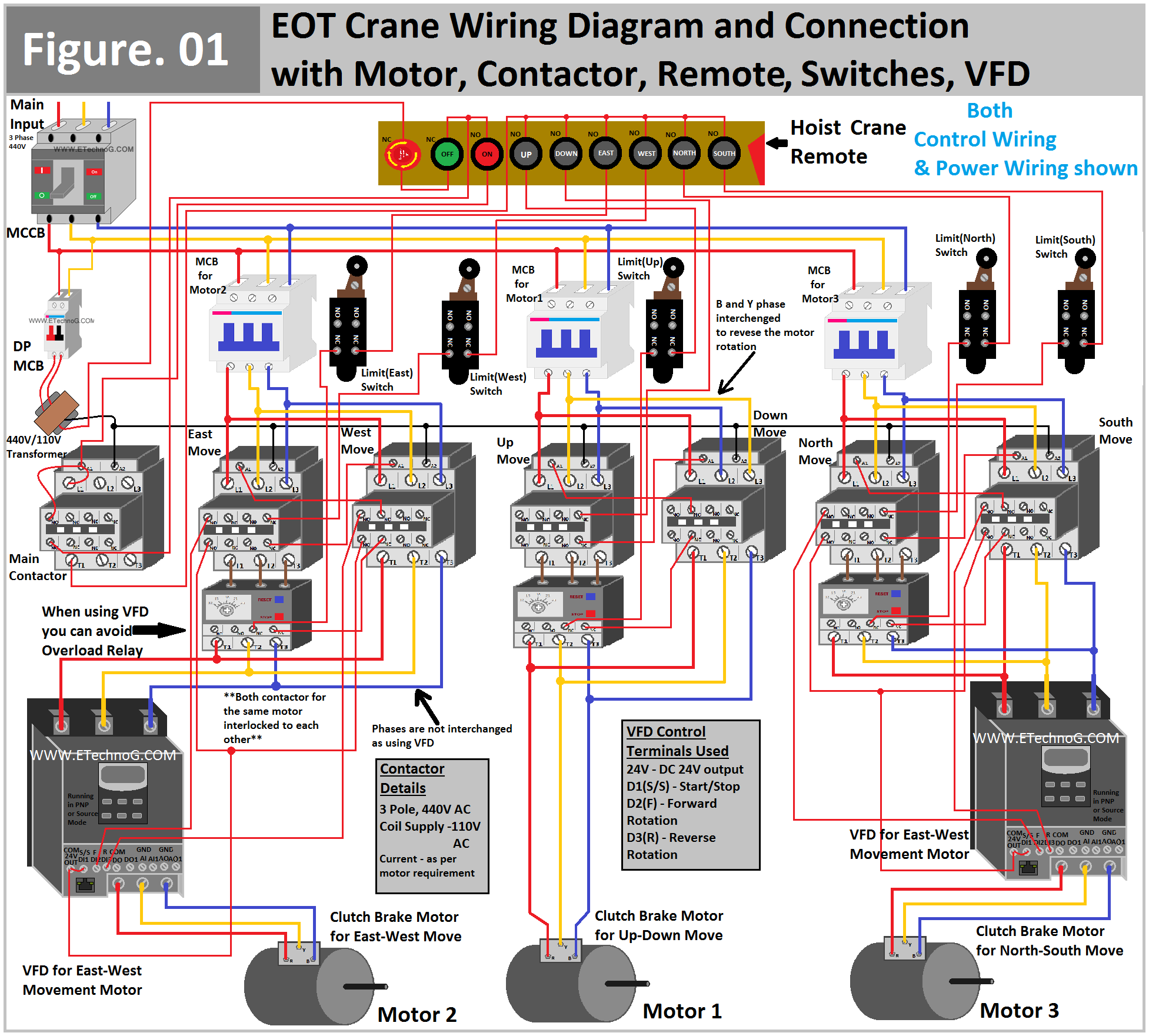

Generally, the hoist moves up and down and the hoist arrangement can move East, West, North, and South sides. The crane that has only up and down movement uses only one motor. The crane that has up, down, East, and West movement uses two motors. The crane that has movement on all sides uses three motors.

EOT Crane Wiring Diagram

Here, you can see the Wiring Diagram of EOT Crane for movement on all sides.

Read Also:

Devices used for this Connection

MCCB

A 3 Pole MCCB is used as a main switch. The main input 3 phase 440V power supply is connected to its input and the output of this MCCB is powering the whole circuit. A 4-pole MCCB can be used if your circuit uses neutral also.

MCB

A double-pole MCB is used for the control circuit. Two phases R and Y are connected to the input of this MCB and the output is connected to the step-down transformer that powers the whole control circuit.

Here, three numbers 3 pole MCBs have been used that powers the power circuit. Each MCB powers a single motor. For example, MCB 1 is powering Motor 1, MCB 2 is powering Motor 2, and MCB 3 is powering Motor 3.

Contactor

You can see, here we have used a total of seven contactors. Here, all contactors are 3 Pole, 440V rated. Coil supply 110V AC. The current handling capacity of the contactor depends upon the motor's current rating. The main contactor is used for the control circuit so a low current rating contactor can be used. Rest all the contactors are should be high current rated as per the motor current rating.

Here, the first contactor also known as the main contactor powers the control circuit when it is turned on the control circuit will be activated.

The rest of the six contactors are powering the three motors. Every single motor is connected to two contactors. One contactor is for forward rotation and another contactor is for reverse rotation.

Thermal Overload Relay

Here, a total of three thermal overload relays are used. We have used overload relays for the Up, East, and North movements. If you using VFD then you may not need to use an overload relay as the VFD gives protection itself.

Step-Down Transformer

Here, the control circuit is designed to operate with a 110V AC supply. That is why we have used a 440V/110V step-down transformer. If your control circuit operates with 230V or other voltages then you may need another transformer as per your requirement.

Limit Switches

A limit switch is used to stop the motor or movement when the crane moves to reach the last end. Here, we have used a total of 5 limit switches. Only for the downward movement, we have not used any limit switch. Also, not that we use the NC terminals of the limit switch.

VFD(Variable Frequency Drive)

Here we have two VFDs for East-West Motor and North-South Motor. For the Up-Down motor, we haven't used any VFD.

Motor

Clutch Brake motors are used in EOT cranes. It provides instant Stoping. Here 3 motors are used for six directions of movement. For example, when Motor 1 rotates in the forward direction hoist will move in the upward direction, and when Motor 1 rotates in the reverse direction hoist will move in the downward direction.

When Motor 2 rotates in the forward direction hoist will move in the East direction, and when Motor 2 rotates in the reverse direction hoist will move in the West direction.

When Motor 3 rotates in the forward direction hoist will move in the North direction, and when Motor 3 rotates in the reverse direction hoist will move in the South direction.

Remote Controller

Here, we have used a wired remote controller that has a total of nine switches including an emergency switch, an On Switch, and an Off Switch. Here, the emergency switch is an NC switch, the On switch is a NO switch, the Off switch is an NC switch, and the rest all the switches are NO switches.

Read Also:

EOT Crane Connection Description

MCB Connection

The output of the MCCB is connected to all three MCBs. All three MCBs are connected in parallel. The output of each MCB is connected to two contactors for the same motor. As here we use VFDs so we have not interchanged the power supply terminal of the west and south contactor. Because VFD itself can change the direction of the motor. For the Up and Down motor, we have not used VFD so we interchanged two power supply terminals of the Down contactor to change the direction of the motor. If you did not use VFD then you must need to interchange the power supply terminal of the West and South Contactor.

Contactor Connection

Two contactors for the same motor are connected parallel to each other(interchange terminal where needed). The input of the contactor comes from the MCB output. As the East-West and North-South Motor uses VFD so the output of these contactors is connected to the VFD and the output of the VFD is connected to the motor. On the other hand, the Up-Down motor does not use VFD so the output of the contactor is directly connected to the Motor.

Remote Switches Connection

The neutral from the output of the step-down transformer is connected to the negative terminal of the coil of all the contactors. The positive terminal from the transformer goes through the Emergency switch, NO switch, and NC switch in series to the positive terminal of the main contactor coil. To hold the main contactor the NO terminals are used. Now the positive terminal of the 110V output transformer goes through the main contactor power terminal and is connected to the input of all the push button switches used for movement.

The output from the Up push button goes through the NC contact of the Up Limit switch, the NC contact of the Up overhead relay, and is connected to the coil of the Up contactor by interlocking the Down contactor.

The output from the Down push button is connected to the coil of the Down contactor by interlocking the Up contactor.

The output from the East push button goes through the NC contact of the East Limit switch, the NC contact of the East overhead relay, and is connected to the coil of the East contactor by interlocking the West contactor.

The output from the West push button goes through the NC contact of the West Limit switch and is connected to the coil of the West contactor by interlocking the East contactor.

The output from the North push button goes through the NC contact of the North Limit switch, the NC contact of the North overhead relay, and is connected to the coil of the North contactor by interlocking the South contactor.

The output from the South push button goes through the NC contact of the South Limit switch and is connected to the coil of the South contactor by interlocking the North contactor.

VFD Connection

Here, VFDs operate in PNP or Sourcing Mode which means they generate 24V DC output. So the 24V output from the East-West VFD goes through the East Contactor NO Terminals and is connected to the Forward Command terminal of the VFD itself. Same the 24V output from the East-West VFD goes through the West Contactor NO Terminals and is connected to the Reverse Command terminal of the VFD itself.

On the other hand, the 24V output from the North-South VFD goes through the North Contactor NO Terminals and is connected to the Forward Command terminal of the VFD itself. Same the 24V output from the North-South VFD goes through the South Contactor NO Terminals and is connected to the Reverse Command terminal of the VFD itself.

Here, we have shorted the 24V output and Start/Stop Terminals of the VFD so it can start automatically when the VFD gets power.

Read Also:

Thank you for visiting the website. keep visiting for more updates.