Difference between Auxiliary and Main Contacts in Contactor

You can easily make a connection for a contactor for any application without any confusion when you have a clear understanding of the types of contacts in a contactor. There are mainly two types of contacts in an electrical contactor - 1. Main Contacts or Power Contacts and 2. Auxiliary Contacts. So, let's go to know the difference between Auxiliary and main contacts in a contactor with their functions, use, and purposes.

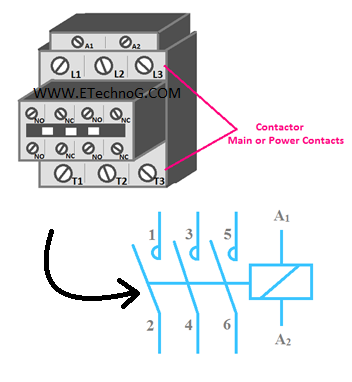

Main or Power Contacts in Contactor

It is the main contact mechanism in an electrical contactor which is used to connect the load to the source. The main contacts or power contacts in a contactor are designed to carry high current and high voltage. The number of power contacts in a contactor depends upon its Pole rating means in a two-pole contactor there are two main contacts whereas in a three-pole contactor, there are three main contacts.

Main or power contacts are NO(normally open) contacts means they will make contacts only when the magnetic coil of the contactor is energized. All of the electrical contactors have the main or power contacts but some of them may not have auxiliary contacts. Main contacts always work with higher voltage and higher current than auxiliary contacts. For example, in a 3-pole 440V contactor, the main contacts are able to work with 440V but in the same contactor, auxiliary contacts may not work with 440V they are only used for the control circuit which uses 220V or less.

Auxiliary Contacts in Contactor

Auxiliary contacts also called helping contacts, that are used for control, indication, alarm, and feedback circuits.

Generally, in a contactor both NO(Normally Open) and NC(Normally Closed) contacts are available. In the above diagram, you can see there is a total of four auxiliary contacts available - two NO contacts, and two NC contacts.

Auxiliary contacts are mainly designed to work with low voltage and low current. Auxiliary contacts help a lot when we make circuits for DOL starter or Star Delta Starter.

Auxiliary contacts help to,

1. Make indication circuits to connect indication lamps such as Green for STOP, Red for START, and Yellow for TRIP.

2. Make feedback circuits for automation systems such as PLC systems.

3. Make loop circuits for the Motor Starter, Controller, etc.

Main Contacts VS Auxiliary Contacts

1. An electrical contactor completes its main function using its main or power contacts whereas auxiliary contacts are only used for control circuits, indicator circuits, or feedback circuits.

2. Main contacts are designed for Normally Open(NO) only whereas Auxiliary contacts are available in both types - NO and NC

3. Main contacts are designed to carry high voltage and high current whereas auxiliary contacts are designed for low voltage and low current only.

4. There is a chance of sparking in main contacts as it carries a high current but in auxiliary contacts, there is no chance of sparking.

If we take the DOL starter as an example to understand Main and Auxiliary Contacts, then we will see, that the main power supply terminals and motor terminals are connected to the main contacts of the contactor. On the other hand, indication lamps, and pushbuttons are connected with auxiliary contacts.

So when the contactor is turned on, the main contacts connect the motor to the power supply and auxiliary contacts help to glow the respective indication lamp so we can understand that the motor is in running condition.